High-Purity Hydrazine Gas Delivery System

Taiyo Nippon Sanso Corporation, a Japanese industrial gas company in Nippon Sanso Holdings Group, has developed a gas delivery system for high-purity hydrazine, compatible with RASIRC’s 1 BRUTE® Hydrazine.

In the electronic device manufacturing industry, hydrazine gas is favored for its superior reactivity over conventional nitriding sources, such as ammonia. This advantage facilitates the reduction of temperatures in the semiconductor manufacturing process, enhances film quality, and improves throughput. Such advancements are crucial for miniaturizing advanced logic semiconductors and increasing the storage capacity of memory 2

TNSC offers RASIRC’s BRUTE® Hydrazine as a high-purity material specifically for semiconductor 3 BRUTE® Hydrazine, prepared by blending anhydrous hydrazine with a unique organic solvent stabilizer from RASIRC, significantly boosts safety. While high-purity hydrazine gas has attracted attention as an emerging specialty gas for semiconductor manufacturing, a system that can deliver this gas via a concentrated and stable method has not been developed. Given the necessity for consistent delivery of such specialty gases in semiconductor production processes, the availability of a dedicated delivery system has become crucial.

Therefore, leveraging their proprietary gas handling technology, TNSC has pioneered the development of a gas delivery system capable of safely and reliably delivering high-purity hydrazine gas tailored to semiconductor manufacturing processes.

System Overview

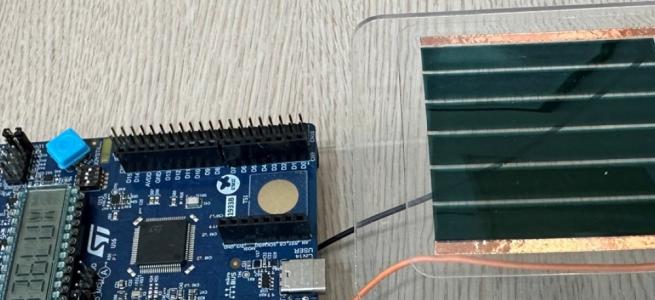

The features of the high-purity hydrazine gas delivery system are as follows:

✓ A BRUTE® Hydrazine vessel is securely housed within the gas delivery cabinet, facilitating the safe and stable delivery of a nitrogen/hydrazine gas mixture ).

✓ The system includes an integrated monitoring feature that continuously tracks the remaining amount of BRUTE® Hydrazine gas, ensuring uninterrupted delivery.

Vessel replacement is streamlined through an automated sequence, allowing for safe and easy maintenance without exposing the hydrazine gas.

✓ The interior of the gas delivery cabinet is maintained under continuous negative pressure to swiftly evacuate any potential gas leaks from the BRUTE® Hydrazine cabinet or internal piping through the exhaust duct, thereby preventing disasters.

✓ In case of hazardous conditions, the system is equipped with a safety feature that triggers an alarm and automatically ceases operation to ensure safety.

Figure 1. High-purity hydrazine delivery system (exterior)